C95400

C95400

Shipping Industry

How strong is aluminum bronze?

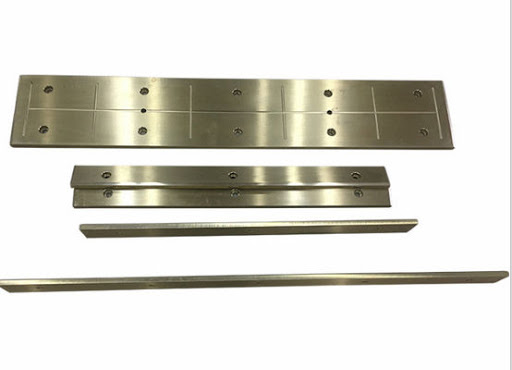

Aluminum bronze materials are mainly used for: acid solution tanks, nuts, gears, sliding parts of rolling mills in rolling mills, and ship equipment parts. It is widely used in fields such as generator sets, shipbuilding, seawater desalination, and petrochemical equipment.

Aluminum bronze has excellent corrosion resistance, so it can be used to make corrosion-resistant parts such as propellers and valves. Moreover, aluminum bronze does not produce sparks under impact and can be used to make non-sparking tool materials. Aluminum bronze has high strength, good anti-friction, and good corrosion resistance, can be hot-processed, welded, and can be used for high-strength, wear-resistant parts, such as bearings, bushings, gears, turbines, etc. Work and other advantages have become a new type of mold material.

The influence of chemical composition on the structure and properties of aluminum bronze has always been one of the hotspots of concern:

- First of all, there is no clear definition of the effect of the chemical composition on the alloy. For example, when the iron is added to aluminum bronze, it generally has the function of refining the grains, reducing the "spontaneous tempering brittleness", and improving the mechanical properties.

- when the iron content is high, the iron will be precipitated as Fe3Al2 compounds, which will change the mechanical properties of the alloy. So the iron content should not exceed 5%.

- There is also a zinc element. Many studies believe that it can improve the plasticity of the metal after a solid solution with the base metal, and some studies believe that it is an impurity element. It can be seen from this that the role of alloying elements cannot be generalized.

It is generally believed that adding an appropriate amount of alloying elements can improve the mechanical properties of the alloy, such as adding an appropriate amount of iron to form aluminum-iron bronze, adding manganese to form aluminum-manganese bronze, and adding nickel to form aluminum-nickel bronze.

Secondly, there is no clear definition of the requirements for the content of impurity elements. It is the change of chemical composition that makes the types and applications of aluminum bronze vary.

Researchers should continue to study the influence and mechanism of chemical composition to further expand the scope of application of aluminum bronze.

Please contact me for information on how to choose a tin bronze suitable for your application.