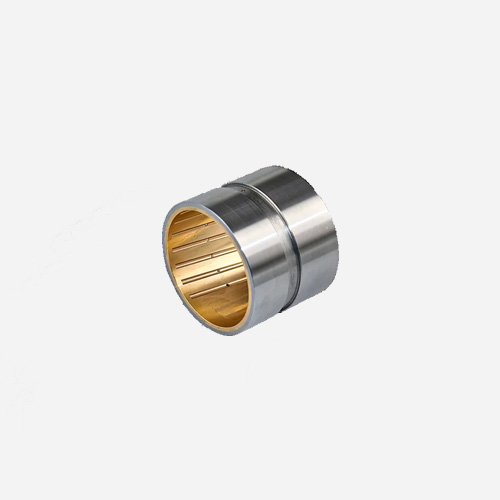

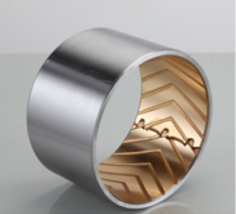

Bimetal bearing

What are bimetal bearings, and how do they work?

The bimetal bearing is based on high-quality low-carbon steel, and the surface is sintered with a low-friction copper alloy (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as the wear-resistant layer of the bearing. The surface of the copper alloy can be used according to the requirements of the working conditions. Process various types of oil grooves, oil holes, oil pockets, etc.

These bimetal bearings have excellent corrosion resistance in industrial outdoor applications as well as in water, marine, and offshore environments, and can be made into a variety of sizes and forms, such as thin-walled, thick-walled, flanged, cylindrical, sintered, and immersed in oil.

Under heavy load and shock load conditions, bimetal bearings have corrosion resistance, are easy to install, and are suitable for emergency replacement. Various oil grooves, oil holes, or oil pockets can be machined on the surface of the alloy layer according to the working conditions. This product is suitable for rocking motion and rotating motion under high load and low speed. It has the characteristics of low friction coefficient, good wear resistance, long service life, and good seizure resistance.

The balance bridge bushings of heavy-duty vehicles all use bimetal bearings, which is a kind of high-load and low-speed motion bearing with a wide range of uses.

In the high sliding performance, it has particularly good self-lubricating performance in the absence of lubricating medium and water as the medium. It is suitable for bimetal casting materials, corrosion-resistant bearings with high sliding speed, and bearings for crushers, water pumps, and cold rolling mills. Piston pin sleeves with a load of 70 MPa.

The material of the bimetal bearing

1. Substrate material:

- low-carbon steel

- the outer surface can be plated with copper or tin with a corrosion-resistant layer.

2. Inner wall copper layer:

- The inner wall copper layer is made of CuSn6Zn6Pb3 or CuSn6.5P0.1 two tin bronzes and CuPb10Sn10 or CuPb24Sn two lead bronzes.

- There are four types of copper layers and ALSn20Cu high-tin aluminum alloy layers.

- Customers can choose the applicable ones. Copper layer material.

- The standard thickness of the alloy layer is 0.25mm-0.3mm, and the alloy layer of any non-standard thickness can also be sintered according to customer requirements.

|

|

|

|

|

|

Send Your Message