Copper Properties

Properties for Aluminum Bronze Grade ZCuAl9Fe4Ni4Mn2

As an Aluminium bronze casting manufacturers, need to understand copper expertise All elements reduce the electrical conductivity and thermal conductivity of the copper rod without exception.

All elements are dissolved in the copper rod, causing the lattice distortion of the copper rod and causing wave scattering when the free electrons flow in a directional direction, Which increases the resistivity. On the contrary, there is no solid solubility or few solid solution elements in the copper rod, which has little effect on the electrical and thermal conductivity of the copper rod.

It should be noted that the solid solubility of some elements in the copper rod increases with The temperature decreases drastically and is precipitated as elemental substances and metal compounds, which can not only solid-solution and dispersion strengthen the copper rod alloy, but also not reduce the electrical conductivity much.

- This is an important alloying principle for the research of high-strength and high-conductivity alloys.

- It should be particularly pointed out here that the alloy composed of the four elements of iron, silicon, zirconium (not wrong), chromium, and copper rods is an extremely important high-strength and high-conductivity alloy.

- The single-phase brass rod, bronze rod and cupronickel rod used in engineering have excellent corrosion resistance.

- There are both soft and hard phases in the structure of copper-based wear-resistant alloys.

- During alloying, it must be ensured that the added elements are not only dissolved in the copper rods but also hard phases are precipitated.

- Typical hard phases in bar alloys include Ni3Si, FeALSi compounds, etc., and phase a should not be greater than 10%.

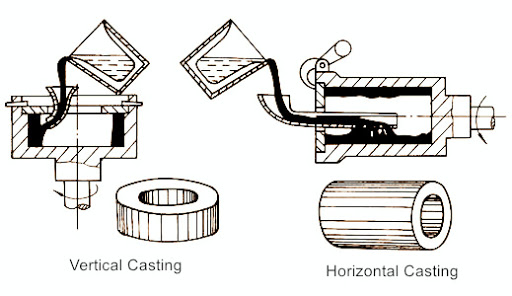

Aluminum bronze casting manufacturers Mainly based on the above two casting methods.

Copper rod alloys with polycrystalline transformation in solid-state have damping properties, such as Cu-Mn series alloys, and alloys with thermoelastic martensite transformation in solid-state have memory properties, such as Cu-Zn-Al, Cu An Al-Mn series alloy:

- The color of copper rods can be changed by adding alloying elements, such as zinc, aluminum, tin, nickel, and other elements.

- As the content changes, the color also changes from red to blue to yellow to white. Change and reasonably control the content will obtain imitation gold materials and imitation silver alloys.

- The selected elements for the alloying of copper rods and alloys should be commonly used, cheap, and pollution-free, and the added elements should be based on the principle of multiple and small quantities, alloy raw materials can be used comprehensively, and alloys should have excellent technology Performance, suitable for processing into various finished products and semi-finished products.

Aluminum bronze casting manufacturers

Tin-phosphorus bronze has higher corrosion resistance, abrasion resistance, and no sparks when punching out. Used for medium-speed, heavy-duty bearings, and the maximum operating temperature is 250°C:

- It has the characteristics of active alignment that is not sensitive to deflection, the bearing is uniformly loaded, the bearing capacity is high, and it can be subjected to radial loads together, and it is self-lubricating without protection.

- Tin-phosphorus bronze is a kind of copper alloy, which has excellent electrical conductivity, is not easy to generate heat, and has strong fatigue resistance to ensure safety.

- The hard-wired electrical structure of the socket of tin-phosphorus bronze, no rivet connection or no conflict contact, can ensure excellent touch, good elasticity, and smooth insertion.

Aluminum bronze A copper-based alloy with aluminum as the main alloying element is called aluminum bronze:

- The mechanical properties of aluminum bronze are higher than brass and tin bronze. The aluminum content of practical aluminum bronze is between 5% and 12%, and aluminum bronze containing 5% and 7% of aluminum has the best plasticity and is suitable for cold working.

- After the aluminum content is greater than 7% to 8%, the strength increases, but the plasticity drops sharply, so it is mostly used in the as-cast state or after hot working.

- Aluminum bronze has higher abrasion resistance and corrosion resistance in the atmosphere, seawater, seawater carbonic acid, and most organic acids than brass and tin bronze. That also can be used to manufacture high-strength anti-wear parts such as gears, bushings, worm gears, and high-corrosion-resistant elastic components

Pipe up with your ideas to our bearing specialist. Contact Us!