Quality Inspection

Bearings are tribological components that carry a load while in contact with and moving relative to another part, which is an indispensable part of the machining and installation process

HARDNESS TESTER

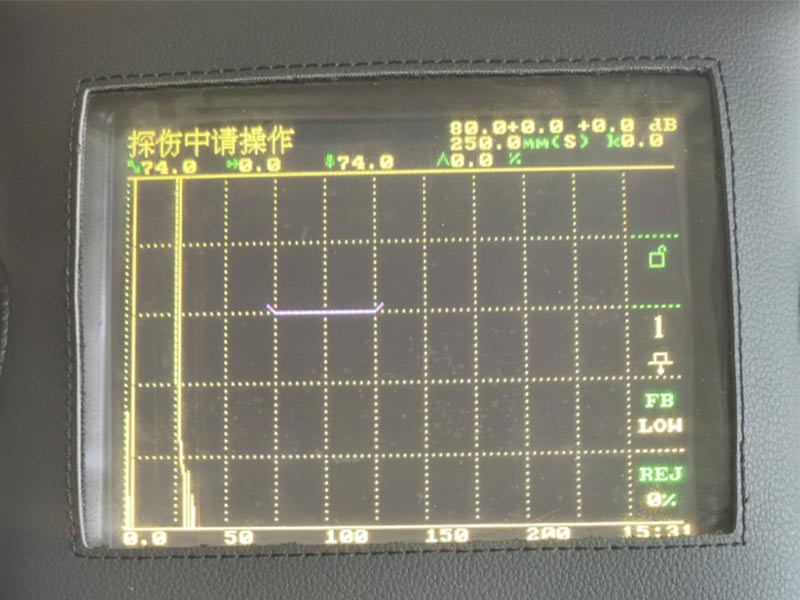

Ultrasonic flaw detector

Roughness measuring instrument

Thermo ARL Optical Emission Spectrometer

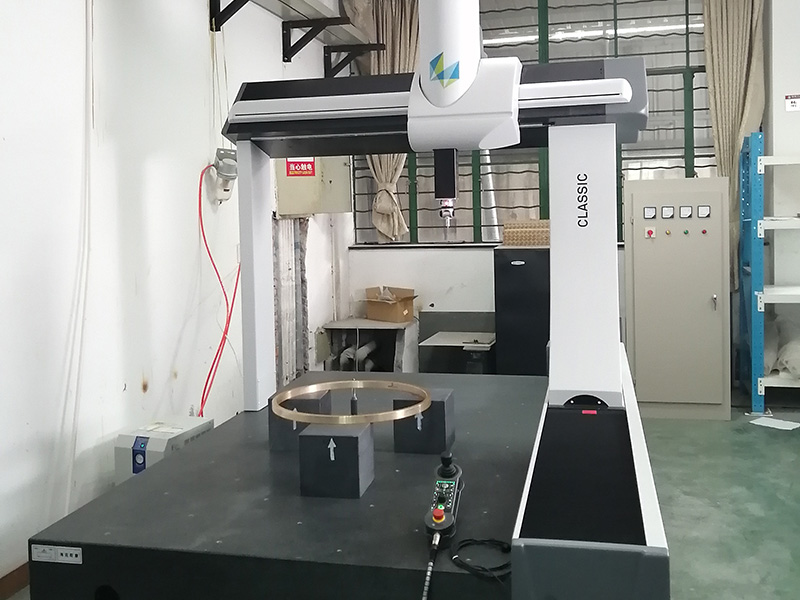

CMM

Flat detector

Spark Direct Reading Spectrometer

Micrometer

Super Micrometer

Tensile Testing Machine

Non-destructive testing (PT)