What are the commonly used materials for copper sleeves?

Two Common Materials For Copper Sleeves

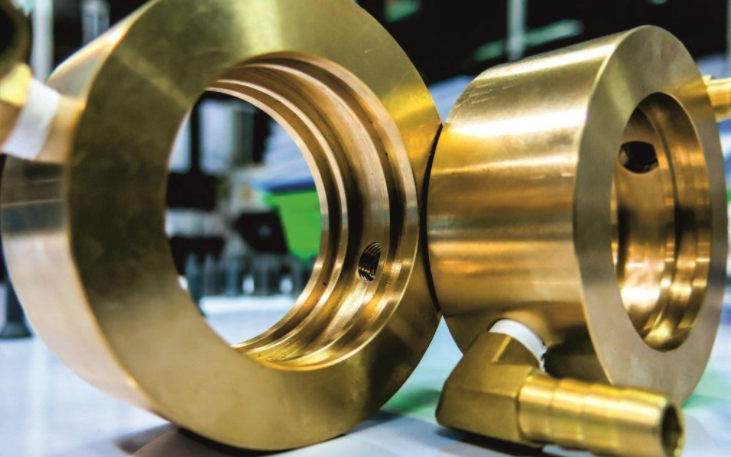

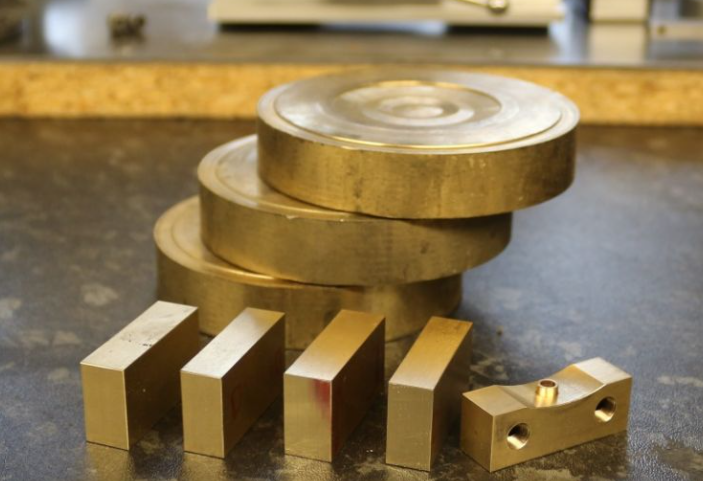

The material of the copper sleeve is mostly composed of brass (alloy of copper and zinc) and bronze.

1. Brass

In order to obtain higher strength, corrosion resistance and excellent casting function, the alloy of aluminum, silicon, manganese, lead, tin, copper and zinc is added to form a special kind of brass. Such as lead brass, tin brass, brass, aluminum manganese silicon brass. Lead brass has excellent cutting performance and good wear resistance. It is commonly used in the casting of wall clock parts, bearings and bushings.

2. Bronze:

①. Beryllium bronze(C17410, C17450, C17460)

The copper alloy with beryllium as the basic element is called beryllium bronze. Beryllium bronze has high elasticity and fatigue strength, excellent wear resistance and corrosion resistance, excellent electrical and thermal conductivity, and has the advantages of non-magnetism and no sparks when subjected to impact.

②. Aluminum bronze(C95400, C95500)

The content of aluminum in theoretically used aluminum bronze is between 5-12%, and aluminum bronze with 5-7 percent aluminum is suitable for plasticity. After the aluminum content is 7% to 8%, the strength is added, but the plasticity drops sharply. Aluminum bronze manufactures high-strength parts such as gears, sleeves, preheating, and high-corrosion-resistant elastic components.

③. Tin bronze(C83600, C90710)

Tin bronze is commonly used in shipbuilding, chemical industry, machinery, instrumentation occupations, and is mainly used in the manufacture of bearings, bushings and other parts for wear, tensioning and resistance, antimagnetic parts, etc.