What is leaded bronze

932 bronze properties?

Research on high-performance copper-based alloys has attracted widespread attention, mainly because the material has the advantages of high strength, low friction coefficient, and good wear resistance.

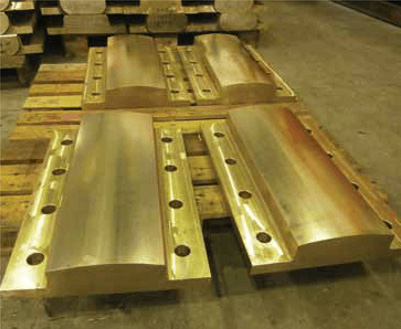

With the deepening of research, people have gradually developed various wear-resistant copper alloys, and the alloys have high strength, mainly including tin bronze, aluminum bronze, leaded bronze, etc., which are widely used in wear-resistant parts such as bearings and bushings. In order to obtain a copper-based alloy with better performance, ZQPb10-10 and ZQSn6-6-3 were selected as comparative test materials this time to study the new lead bronze alloy. In this experiment, a new type of wear-resistant lead bronze was prepared using electrolytic copper, pure tin, pure nickel, brass, lead, and rare earth as raw materials using the melting and casting method.

In the experiment, the mechanical properties and tribological properties of the copper alloy were studied. Test the tensile strength of copper-based alloys by using a universal material testing machine:

- Under different load and sliding speed conditions, the friction and wear properties of the copper alloy were tested by the ring block wear tester.

- The test results show that the lead bronze alloy has higher strength than ZQPb10-10 and ZQSn6-6-3. The addition of alloying elements tin, nickel, and rare earth improves the structure of the alloy, strengthens the matrix, and further improves the mechanical properties of the alloy.

- When the wear conditions are the same, the friction coefficient of the new lead bronze is smaller than that of the comparative material. In the same wear time, the sample wear volume is smaller.

- The friction coefficient of the leaded bronze alloy decreases with the increase of lead content, and the friction coefficient of the sample is the smallest when the lead content is 17%.

The wear volume of the sample is related to the hardness, load, and speed of the sample. With the help of a metallurgical microscope (OM), scanning electron microscope (SEM), energy spectrum analysis (EDX), and other analysis and testing methods, the structure, composition, morphology, and other performance characteristics of copper-based alloys have been systematically studied.

Research indicates:

- In lead bronze alloys, lead is distributed on the copper matrix as soft points.

- The anti-friction phase and refined structure in the alloy are very beneficial to improve its wear resistance.

- Under oil lubrication conditions, when the load is low, the wear mechanism of the alloy is mainly adhesive wear. With the increase of load, the wear mechanism is adhesive wear, abrasive wear, and fatigue wear.

- Lead is not solid-soluble in copper, and its solid solubility in copper alloys is also very small, and it forms an easily soluble eutectic structure with copper. In the solid-state, lead is distributed in copper as a simple substance and can be distributed in the crystal and the crystal.

In the lead-containing copper alloy, the lead in the crystal can be transferred into the crystal when it undergoes phase change or recrystallization. Lead has no significant effect on the electrical and thermal conductivity of copper and alloys, but it can improve the cutting performance. Lead is a solid phase, which is exactly what bearing materials want. Therefore, lead-containing copper and alloys are valuable free-cutting materials and bearing materials. Because of its low cost, it is more popular in the market. Lead-containing brass is extremely widely used. The smaller the lead is, the more uniform the distribution, and the better the performance.

Lead-containing copper and alloys can be used in as-cast or pressure-processed. Lead-containing brass It is single-phase β at high temperature (above 500°C), which has excellent thermal processing performance and can withstand large thermal deformation.

At normal temperature, f is in the α phase and α+β phase regions, the deformation resistance is large during cold deformation, the plasticity is poor, and the excessive processing rate will cause the alloy material to crack; With the development of science and technology, the lead content of conventionally used lead brass has increased from 0.8-2.5% to more than 5%. New types of lead-containing copper, brass, bronze, and cupronickel are continuously being developed; especially It is pointed out that lead-containing copper alloys are extremely adaptable to raw materials, and recycled copper can be used directly to produce lead-containing copper alloys, which is very important for copper processing enterprises.